Mobile 3D scanning is revolutionizing the way professionals collect morphological data in the O&P sector. Thanks to this scanning solution, it is now possible to obtain accurate 3D models of the human body in seconds! Discover in this article how the mobile capture experience surpasses handheld hardware scanners.

Hardware versus Software

The reality of the handheld 3D scanner : physical constraints

These are devices designed as pure measurement tools. They rely on proprietary physical sensors whose performance is fixed by the hardware. The operation of a traditional professional scanner imposes a certain heaviness. The practitioner must deal with the bulkiness of the device and often the need to have a high-performance computer nearby to process the data.

Mobile 3D scanning revolution : software agility

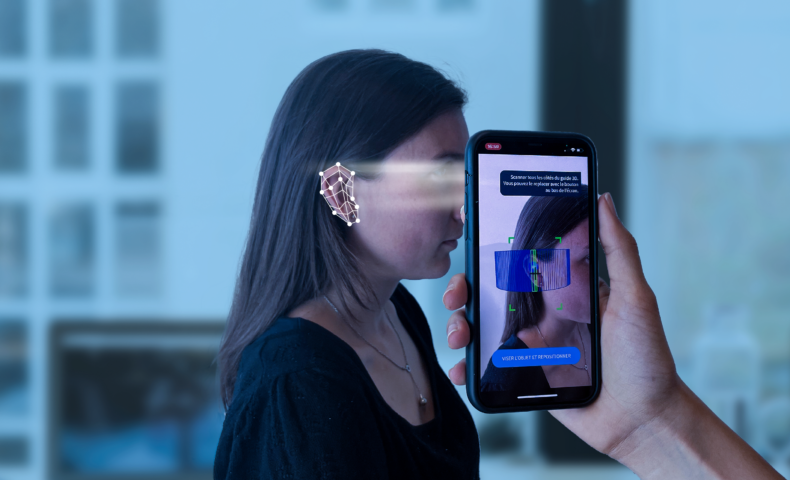

The solution is based on a 3D scanner for phones (SaaS software solution) that uses your smartphone’s rear cameras. Mobile 3D scanning uses a tool that your teams and customers already own. Our proprietary 3D modeling technology shifts all the intelligence into the software. Your solution continuously improves via updates, without hardware changes.

Some applications use the LiDAR sensor. However, LiDAR is limited for the millimetric precision of a human limb. MyFit Solutions technology uses advanced photogrammetry via the rear cameras. The optical resolution offers superior data density, essential for manufacturing custom-made devices.

Medical precision : Is mobile 3D scanning up to the task ?

The strength of algorithms : from pixel to volume

Thanks to photogrammetry coupled with AI, algorithms reconstruct a volume faithful to scale. The final result is a high-quality 3D mesh, photorealistic and ready for CAD software.

The “clean” file : the advantage of automation

A traditional hardware scanner often captures useless data. The mobile 3D scanning experience is automated: it delivers a clean, scrubbed STL or OBJ file, with 98% validated precision and ready for production. This is time saved directly for your technicians who no longer have to manually process the mesh.

“Now that our orthopedists tried it, they will never go back to 3D scanning with additional hardware!” – Eric Moreau, 03D President

Real-world usage : The agility of mobile 3D scanning

Total mobility : “Scan different, anywhere, by anyone”

Imagine scanning a patient in their hospital bed. With a handheld 3D scanner, it’s a challenge. With mobile 3D scan, it’s natural. Whether it’s a limb scan or a full-body scan need for compression garments, you are operational instantly, regardless of the environment.

At MyFit Solutions, we offer a simple, intuitive, and accessible user experience. The application guides the user step-by-step to ensure that the capture is perfect. Any employee can perform a medical-precision scan from the first use.

Operational efficiency : Why flexibility wins over hardware

Lifting hardware constraints

Beyond the technique, the handheld scanner imposes inertia: dependence on maintenance, logistical complexity, and a high risk of failed scans without guidance.

Scalability: democratizing scanning throughout your network

With mobile 3D scanning, you scale up. Deployment is immediate via simple software access. It is the only way to truly industrialize the creation of custom-made products at scale.

A measurable ROI

Our approach allows for the generation of concrete benefits:

+50% operational efficiency: Fewer manual steps and speed of use.

-50% return rate: Fewer remanufactures thanks to the reduction of measurement errors.

The verdict is final : for the majority of professional applications, mobile 3D scan surpasses traditional hardware through its agility and deployment capacity. By adopting this technology, you move from a constrained artisanal model to a high-performance digital model, ready for the challenges of tomorrow.