Ensuring optimal comfort when wearing eyewear requires precise facial analysis. Discover how 3D scan technology from smartphones is revolutionizing the creation of custom made glasses. And explore the new opportunities it offers retailers, even at a distance! Are you ready to transform the eyewear shopping experience?

How to create glasses?

Requirements for a good measurement

Taking measurements is a crucial step in the making of eyeglass frames. Qualified opticians have the mission to ensure visual comfort and visual health of their customers. They offer them optical and solar glasses fitting their morphology and their needs.

Today, buying properly fitted glasses requires a comprehensive set of data:

- Size and positioning of the eyes: measurements related to pupillary distance, nasal width or canthus level are essential to ensure optimal vision and wearing comfort.

- Size and positioning of the eyes: measurements related to pupillary distance, nasal width or canthus level are essential to ensure optimal vision and wearing comfort.

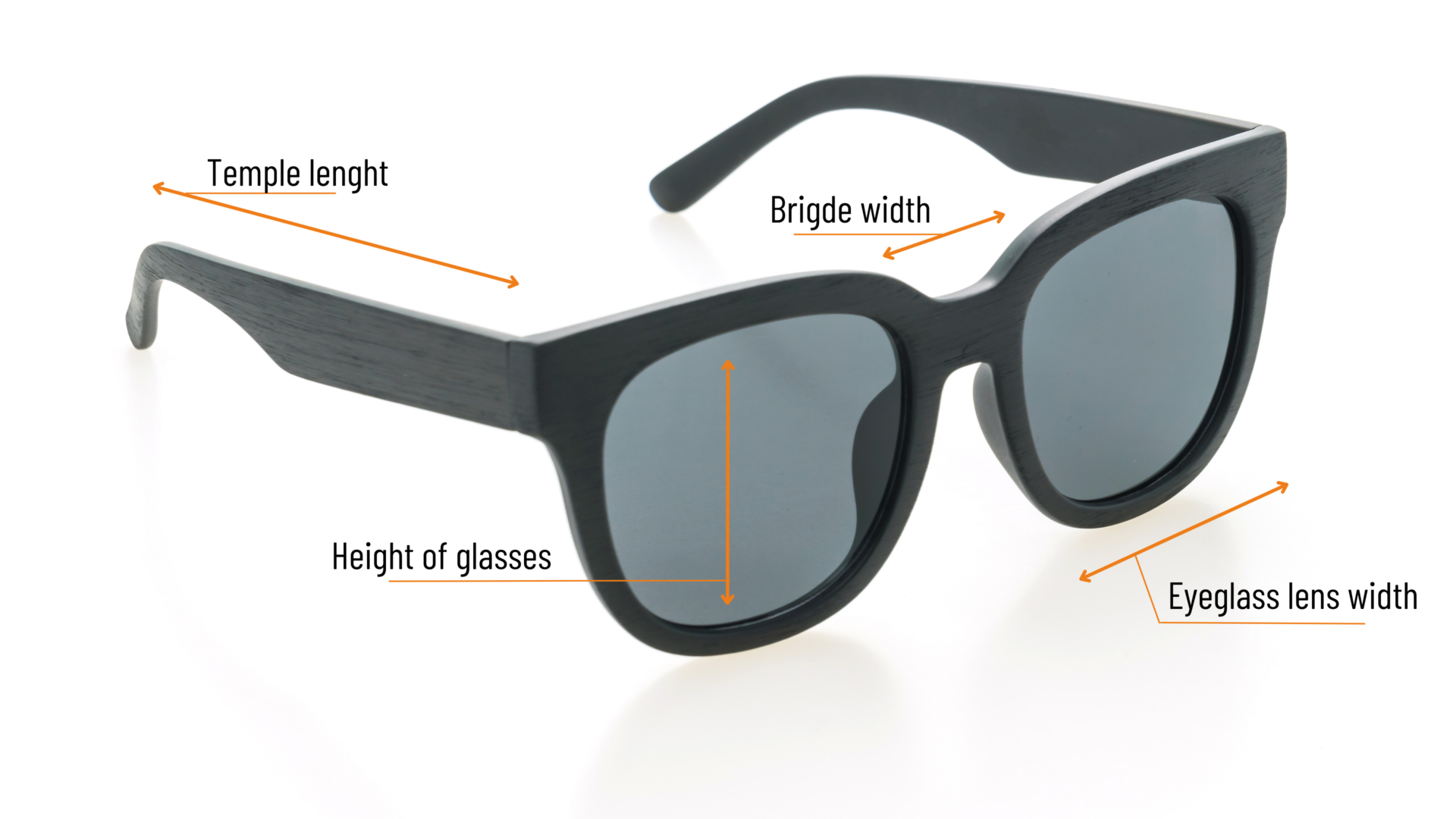

- Eyeglass lens width: width of eyeglass lens must be adapted to the size of the eyes and the wearer’s field of vision.

- Bridge width: a correctly sized bridge avoids excessive pressure on the wearer’s nose.

- Temple length: length of temple must be defined as to ensure a stable hold behind the ears without causing discomfort.

- Sphenoidal and temporal distance: these measurements are taken to ensure a balanced distribution of the frame‘s weight on the face and to avoid uncomfortable pressure points.

It is important to note that these measurements should be taken by an optical professional, such as an optician or spectacle maker. Someone who has the necessary skills and expertise.

Optical market challenges: e-commerce and customization

The French optical market is experiencing significant growth, with total sales of €6.75 billion in 2021, up 13.5% from 2020. It is interesting to note that the market share of online optics (e-commerce) is growing and now exceeds 7%.

However, the development of e-commerce raises questions about how to ensure accurate and efficient measurement by the patient. Indeed, how to take measurements at a distance without physical interaction? How to get reliable measurements without the intervention of a professional? How to make custom made glasses remotely?

The solution to these challenges lies in 3D scanning from smartphones. This innovative technology allows to take accurate measurements remotely for custom glasses manufacturing and right glasses frame recommendation.

Face 3D scan for custom made glasses design

It is necessary to have a large number of measurements in order to take into account the entire morphology of the face (including ears). This is where 3D scanning of the face comes into play. Indeed, 3D scanning offers the possibility to obtain an accurate 3D model enabling a thorough analysis of each client.

In order to adapt to the specificity of each individual, the 3D scan allows one to examine accurately the different parts of the face: the oval of the head, the eyes, the nose or the ears. Hence, morphological particularities such as a smaller ear or eye can be properly taken into account This is essential for manufacturing a unique product, perfectly adapted to the customer’s morphology.

Thus, 3D face scanning is a key tool in providing customers with eyeglasses and sunglasses that are perfectly adapted to their morphology, style and needs. And benefiting from this technology does not require the investment in an expensive scanner. Indeed, let’s discover in the following paragraph how it is now possible to scan from a smartphone thanks to MyFit Solutions.

3D scanning from a smartphone: how and why?

How to scan from a smartphone ? MyFit Solutions 3D scanning guide

Performing a 3D face scan with a smartphone is now a simple and easy process in just three key steps:

Step 1: Preparation and landmarks

First, be sure to clear the head to be scanned by pinning back or covering the hair. Then, use the person’s ears as landmarks. For a scan without error, MyFit Solutions app has it all! It shows you the correct distance to maintain between you and the subject being scanned and it offers an augmented reality display to guide the scan step by step.

Step 2: Distance and position

Keep the same distance between the phone and the face throughout the process to avoid distortion and ensure consistent data acquisition. The person being scanned must remain still and maintain the same facial expression to get an accurate result. MyFit Solutions interface is designed to make it easy for you to make the right move. Indeed, we indicate in real time when you are too far or too close. Everything is thought to perform a successful scan from the first time!

Step 3: Accurate and complete scanning of the face

During scanning, it is crucial to capture all parts of the face, including the contours, cheekbones, nose, lips, eyes, eyebrows and ears! To do this, MyFit Solutions technology displays the areas to be captured on the on-screen guide with boxes to be colored. Scanning then becomes child’s play, everything is thought out so that 3D scan can be done anywhere, anytime and by anyone!

Why use a smartphone as a 3D scanner? The advantages of MyFit Solutions technology

Firstly, using a smartphone as a 3D scanner has the major advantage of accessibility. With smartphones being widely available, the ability to use a 3D scanner on a mobile device puts this technology within reach of everyone, including opticians, eyewear manufacturers and their customers.

Indeed, MyFit Solutions offers both scanning experiences from the rear cameras of any Android phone or iPhone, and an instant 3D scanning solution through the Apple Truedepth sensor (Face ID).

Secondly, the MyFit Solutions 3D scanning smartphone application is designed to be simple, fast and intuitive. This eliminates the need for specific training to obtain an accurate 3D model of faces.

Moreover, our smartphone-based solution opens up a whole new world of possibilities for remote customization of optical frames and sunglasses. Morphological personalization of the product is accessible anywhere, anytime.

3D face scan by MyFit Solutions for manufacture of custom made glasses

MyFit Solutions offers you an innovative 3D scanning solution accessible from your smartphone. By using our technology, you will enjoy many advantages for the manufacture of tailor made glasses:

- Enhanced customer experience: Provide your customers with a modern and innovative shopping experience, both in-store and online.

- Reduced returns: Our accurate 3D scans ensure a better fit of tailor made eyewear, reducing your product returns rate.

- Ease of use: Our guided application allows in-store professionals and their customers to easily obtain a 3D face scan, which is essential to the creation of custom made eyewear.

- Branding: MyFit Solutions acts as a white label, we create your dedicated application or we provide you with our technology (SDK) for integration into your existing mobile applications.

- Integration to your environments : . Scans are linked to our web platform, facilitating access, tracking, downloading and automated exchanges of scanned 3D models with your’ third-party softwares.

Would you like to adopt 3D face scanning technology for custom eyewear and offer your customers an unforgettable experience?