Helmets, sports goggles, glasses and cosmetic products have one thing in common: the need to be perfectly adjusted to the morphology of the head and face (skull, eye area, mouth…).

3D scanning for tailor-made consumer goods

Do you design products which need to be perfectly adapted to your customers’ morphology? Do you want to make their customer journey easier? Advise on the best size remotely?

Offer your customers a unique 3D scanning experience from their smartphones!

A 3D scanning experience adapted to your needs

Customization

Client satisfaction

Branding

Use cases overview

Tailor-made head and face product manufacturing

Tailor-made head and face product manufacturing

Made-to-measure hand products manufacturing

Made-to-measure hand products manufacturing

For the safety or comfort of final customer, hand products should be perfectly adjusted.

We enable our clients to take hand digital measurements from smartphones to create or recommend the right fit. No more trying on multiple sizes!

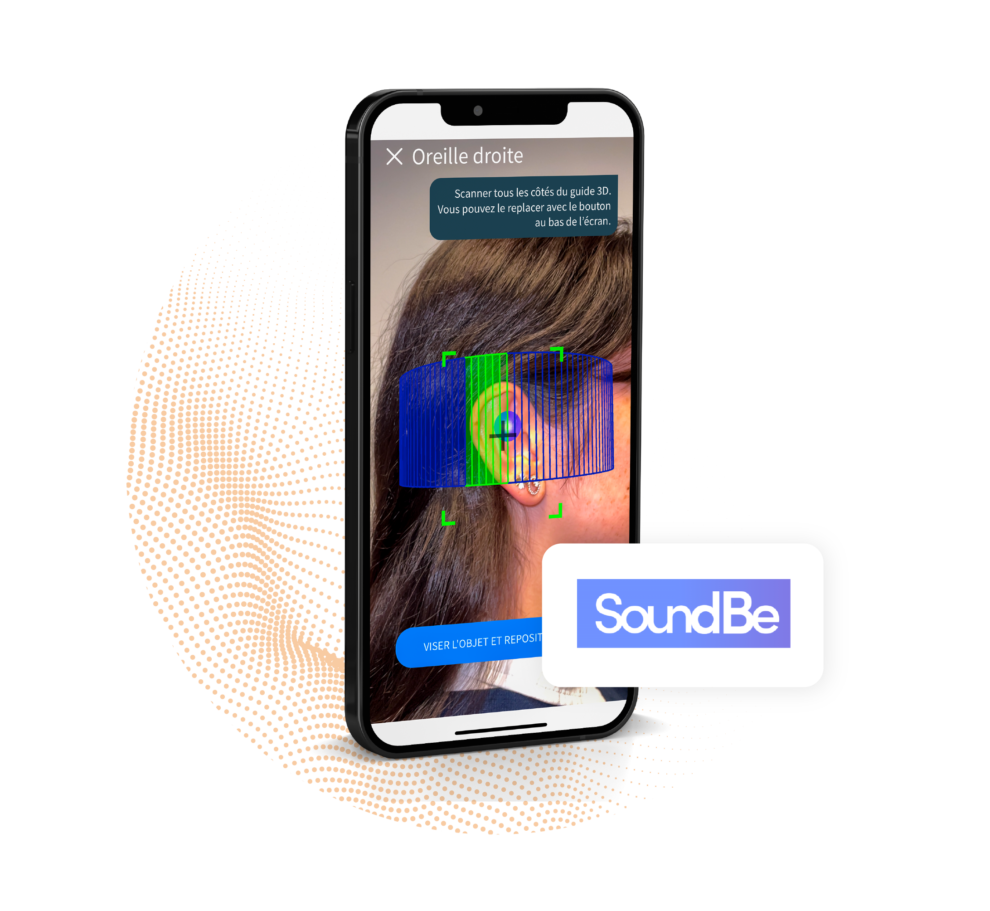

Earplug size recommendation

Earplug size recommendation

Advising customers on the right size of earplugs remotely is the promise that manufacturers can now make to their customers.

With a mobile app developed by MyFit Solutions, customers scan their ears from their smartphones. They obtain instantly the right size recommendation for the product of their choice.

Interested in our solutions?

They trust us

MyFit Solutions: How does it work?

Other applications